CUSTOM-ON-BODY. Defining a design method to customise products according to the population’s varied morphology […] 2nd year

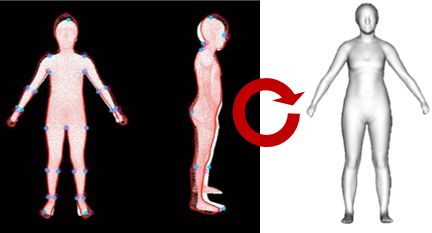

CUSTOM_ON_BODY is a project that will include 3D scanning technologies, user preferences and flexible manufacturing in order to obtain customised products that fully meet people’s requirements, with examples that can be applied to the orthoses and footwear market.

Aims

Most products that people wear require great ergonomic adaptation to the user to ensure their functionality and comfort. Often, this is only possible by customising the product, which is a solution that affords great added value in the development of products that meet potential clients’ emotional and functional requirements.

The development of low-cost 3D scanning systems based on the use of depth sensors has fostered the appearance of new business opportunities in the field of customisation. However, the success of these new products and services calls for development and evolution in two essential technologies in this process:

1. Generating body avatars using accessible, low-cost technology that provides the quality and precision required by the types of products susceptible to customisation

2. Defining a process that enables the customised product to be manufactured and launched on the market demanding it, with costs and deadlines that the potential client finds acceptable.

The CUSTOM ON BODY project (Defining a design method for customising products adapted to the population’s morphological variety, which are manufactured using flexible production technologies) is intended to make headway in the methods and technologies for developing products that use a 3D model of the human body to design and manufacturing customised products adapted to the users’ body shapes, using flexible manufacture technologies.

From the technical point of view, the scope of this project depends on the development of new tools for modelling the human body that enable both qualitative and quantitative information to be obtained, and an improvement in designs that reduces the material used, as well as specifying and setting up flexible production technologies to manufacture customised products.

At the time of writing, the project has been running for one and a half years. The results obtained so far have enabled the following:

1. Markets have been identified in the Valencia Community region that demand customised products based on adaptation to the population’s morphological characteristics.

2. The legal context has been defined to which the customised products must adhere in the markets identified, as well as the specific regulations they must meet to be sold locally, in Spain and in the EU-28.

3. Low-cost commercial systems to record the human body have been identified, evaluating their technical characteristics.

4. The Valencia Community region’s key markets have been selected to create demonstrators for customised products.

5. The most suitable flexible manufacturing technologies for the customisation market have been identified.

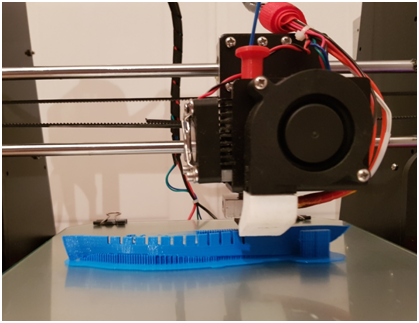

This year, a design method is being developed that helps generate design criteria while enabling customised products to be created using people’s body shapes and dimensions as the benchmark, including optimisation and adaptation of the design to the flexible manufacturing processes available. This method will be validated by creating demonstrators in the sports, footwear and orthopaedics industries.

The CUSTOM_ON_BODY project includes the latest 3D human body scanning technologies together with the user’s preferences in order to use 3D printers to design and manufacture customised products that fully meet people’s requirements. These technologies can be applied to any product we wear: orthoses, clothes, footwear, sports kits, workplace protection equipment, healthcare technology and more.

The guidelines for using flexible manufacturing technologies will put the means of production within reach of companies so as to manufacture customised products at costs and within deadlines that are acceptable to the markets demanding customisation.

The design method developed in this project will increase the potential to add value to the products from companies in the aforementioned sectors in various ways:

1. Firstly, it will give companies applications to be able to create body avatars for their potential clients by using low-cost recording systems. These applications will process the point cloud recorded by the scanner, transforming it into homogenous surfaces from which quantitative and qualitative reference points can be obtained to customise the product for the individual.

2. The combination of avatars with parametric models of the product designed in 3D modelling applications will enable a customised design of the product to be generated quickly, and in some cases automatically. This enables the process to be competitive in terms of cost.

3. The clients’ digital avatars can lead to a new channel for the client-company relationship that bolsters customer loyalty, purchases of new customised products and acquisitions of standard products that can be virtually verified to see if they fit.

4. Based on information about the user, about the limitations of the manufacturing processes and about the design requirements, the protocol for designing products will enable the most suitable manufacturing technology for customisation to be identified. The relationship between the types of customised product and certain flexible manufacturing technologies will be confirmed by carrying out the project.

Collaborating companies

Coordinator:

Instituto de Biomecánica (IBV)

Partners:

Instituto Tecnológico Metalmecánico, Mueble, Madera Embalaje y Afines (AIDIMME)

Companies cooperating in the project:

BIOMECH CONSULTING S.L.

CALZAMEDI S.L.

CREASOLID S.L.

EMO - ESPECIALIDADES MÉDICO ORTOPÉDICAS S.L.

ORTOPEDIA MOLLÁ S.L.

TEQUIR, S.L.

Duration and reference no.

Start date: 01-01-2017

End date: 31-01-2018

Project reference no.: IMDEEA/2017/57

Project funded by IVACE as part of the aid programme for technological centres in the Valencia community region to carry out R&D projects of a non-economic nature in cooperation with companies for the 2017 fiscal year, 50% co-funded by the European Regional Development Fund (ERDF) through the 2014-2020 ERDF Operational Programme for the Valencia Community region.

Referencia: IMDEEA/2017/57